Precision every step of the way

Production

This is how we produce our high-quality scissors:

- on a production area of over 1000sqm,

- with a highly qualified team,

- with state-of-the-art CNC machines and robots,

- with gold bath, electric polishing belt which guarantees fast and flexible order processing,

- with laser and passivation bath,

- with optimized stocks, so we can supply you quickly and at short notice.

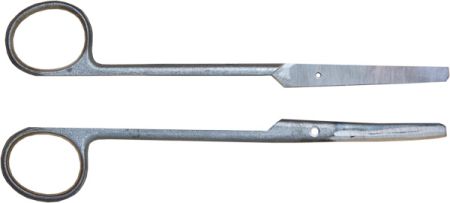

What are the steps in the production of a pair of scissors?

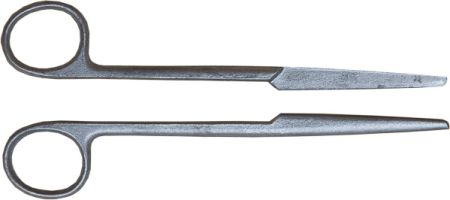

1. Schritt / Step

Rohware / forging

2. Schritt / Step

Gebohrt, gefräst / drilled, milled

Stangen und Ringe geschliffen / shankes and rings ground

HM ausgeschliffen / carbide ground

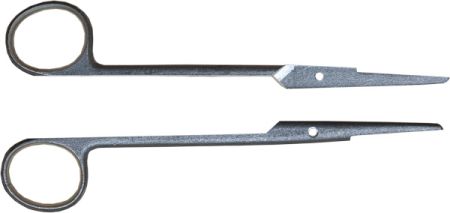

3. Schritt / Step

Gebogen / curved

Hartmetall aufgeschweißt / carbide welded

4. Schritt / Step

Manuell vorgeschliffen / manually pre-ground

5. Schritt / Step

CNC geschliffen / CNC ground

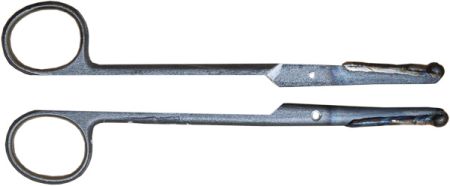

6. Schritt / Step

Montiert, gerichtet zum Härten vorgeschliffen /

assembled, adjusted

zum Härten vorgeschliffen / pre-ground for hardening

7. Schritt / Step

Gehärtet, angelassen / hardened, tempered

Schluss und Spiegel anpoliert / box lock polished

Ringe poliert / rings polished

8. Schritt / Step

Montiert, hartgerichtet / assembled, hard adjusted

formgeschliffen zum Polieren / ground to shape for polishing

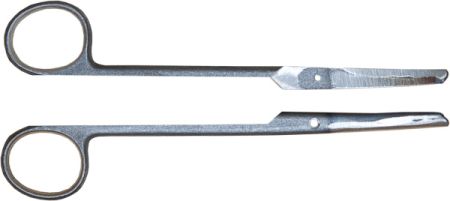

9. Schritt / Step

Komplett poliert / completely polished

10. Schritt / Step

Demontiert / demounted

Ringe poliert, elektropoliert / rings polished, electropolished

11. Schritt / Step

Montiert, gerichtet, geschärft / assembled, adjusted, ground

12. Schritt / Step

Ringe vergoldet / rings gold plated

mattiert, ausgewaschen / matted, ultrasonic-cleaned

und kontrolliert / and controlled

Data protection

Protecting your data is a matter of course for us. Please find out more about the details.

General Terms and Conditions / Legal Notice

Please find here our general terms and conditions and our legal notice.